Air Cooled Oil Cooler Manufacturers in Delhi

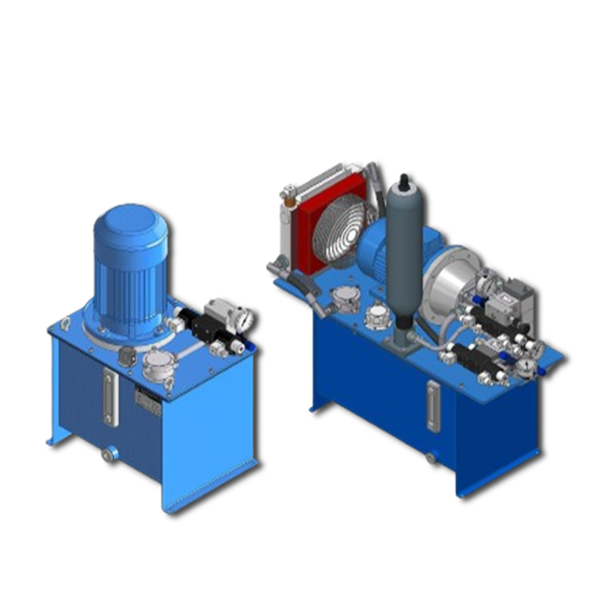

Erika Fluid Power is the best Air Cooled Oil Cooler Manufacturers in New Delhi. Our air-cooled oil coolers retain supreme cooling efficiency, ensuring that all of your machinery comes under the temperature range for which it is designed. The coolers pass the heat quickly and maintain the oil's viscosity and lubricating properties intact, guaranteeing that overheating does not occur and that smooth operation of the system is ensured. Our products' enhanced and reliable cooling capability helps reduce the wear and tear caused by your equipment, extending its life and reducing the associated maintenance costs.

Air Cooled Oil Cooler Exporters from Delhi

We are the punctual Air Cooled Oil Cooler Exporters from Delhi. The air-cooled oil coolers exude durability. These are made using high-grade raw materials, they are strong enough to survive with grace under the most strict and monitored operating conditions and temperature extremes. The sturdy construction of our oil coolers makes them work without a hitch in even the toughest surroundings. This durability offers long-term cost savings by knowing you can count on our coolers to do their intended job efficiently, eliminating frequent replacements or repairs. Our air-cooled oil coolers are compact and lightweight, which makes them quite easy to install and integrate into existing systems. It also saves space by offering a compact design that simplifies installation, therefore reducing downtime and lowering related labor costs. Also, these are super reliable because they come in small sizes do not compromise performance, and are designed to extract efficient cooling in a very small footprint area.

Air Cooled Oil Cooler Suppliers in India

Consider us for all the needs of your Air Cooled Oil Cooler wholesale Suppliers in India. One of the major advantages of our air-cooled oil coolers is that it has very low maintenance requirements. These coolers are designed for easy access, reducing the time it takes for any sort of maintenance to a minimum. High-quality materials and intelligent design guarantee that our coolers will work with minimum intervention, occupying the minimum possible attention of your team by unnecessary recurring maintenance.

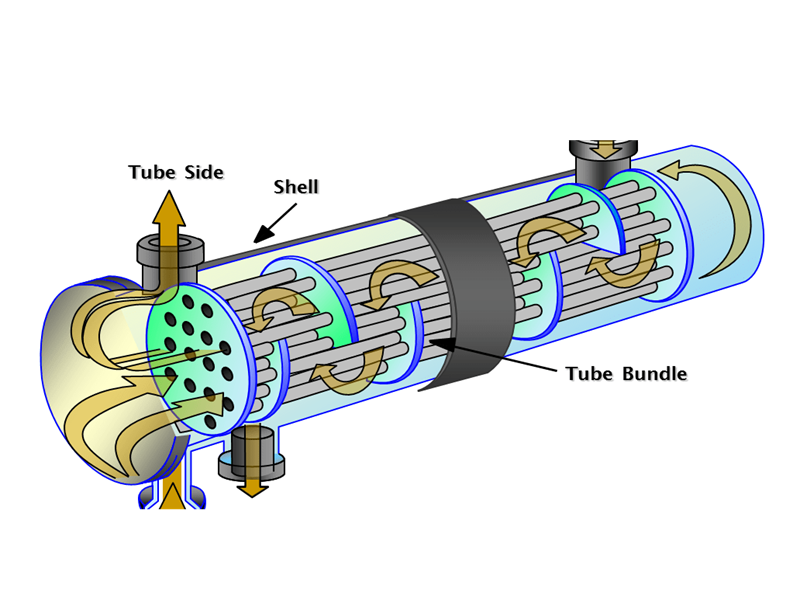

An air-cooled oil cooler is a heat exchanger that cools hydraulic or lubricating oil by dissipating heat into the surrounding air. It’s widely used in various industrial and mobile applications where airflow is sufficient for cooling. Here’s a detailed description of air-cooled oil coolers:

| Model No. | Oil Flow LPM | Fan Size Inch(mm) | No of Fans | Phase | Power Source | Voltage V | Frequency HZ | Current A | Noise dBM | Capacity Kcal/h (∆T=25°C) | Motor HP | Dimension LxHxW |

| EFP-L-608 | 1-12 | 6"(150) | 1 No | 1P | AC | 230 | 50 | 0.25 | 54 | 660 | 250x203x110 | |

| EFP-W-0608 | 1-12 | 6"(150) | 1 No | 1P | AC | 230 | 50 | 0.25 | 55 | 450 | 310x200x108 | |

| EFP-W-0608-F2 | 1-12 | 6"(150) | 2 No | 1P | AC | 230 | 50 | 0.25 | 58 | 1250 | 410x200x108 | |

| EFP-H-0608 | 3-60 | 6"(150) | 1 No | 1P | AC | 230 | 50 | 0.25 | 56 | 1000 | 305x200x115 | |

| EFP-H-0608-F2 | 3-60 | 6"(150) | 2 No | 1P | AC | 230 | 50 | 0.25 | 50 | 2000 | 405x200x115 | |

| EFP-H-1012-1P | 20-120 | 10"(250) | 1 No | 1P | AC | 230 | 50 | 0.23 | 52 | 4167 | 3-5 | 417x360x200 |

| EFP-H-1012-3P | 20-120 | 10"(250) | 1 No | 3P | AC | 415 | 50 | 0.217 | 52 | 4167 | 3-5 | 417x360x200 |

| EFP-H-1215-1P | 20-140 | 12"(300) | 1 No | 1P | AC | 230 | 50 | 0.42 | 59 | 4583 | 5-7.5 | 510x390x210 |

| EFP-H-1215-1P | 20-140 | 12"(300) | 1 No | 3P | AC | 415 | 50 | 0.22 | 59 | 4583 | 5-7.5 | 510x390x210 |

| EFP-H-1418-1P | 30-150 | 14"(350) | 1 No | 1P | AC | 230 | 50 | 0.65 | 75 | 8333 | 7.5-10 | 570x420x285 |

| EFP-H-1418-3P | 30-150 | 14"(350) | 1 No | 3P | AC | 415 | 50 | 0.38 | 75 | 4583 | 5-7.5 | 510x390x210 |

| EFP-H-1428-1P | 30-200 | 14"(350) | 1 No | 1P | AC | 230 | 50 | 0.65 | 75 | 10833 | 15-20 | 570x420x230 |

| EFP-H-1428-3P | 30-200 | 14"(350) | 1 No | 3P | AC | 415 | 50 | 0.38 | 75 | 10833 | 15-20 | 570x420x230 |

| EFP-H-1490-1P | 30-260 | 14"(350) | 1 No | 1P | AC | 230 | 50 | 0.65 | 60 | 13,333 | 20-25 | 520x640x300 |

| EFP-H-1490-3P | 30-260 | 14"(350) | 1 No | 3P | AC | 415 | 50 | 0.38 | 60 | 13,333 | 20-25 | 520x640x300 |

| EFP-H-1680-1P | 30-280 | 16"(400) | 1 No | 1P | AC | 230 | 50 | 0.82 | 76 | 17,500 | 25-40 | 520x640x320 |

| EFP-H-1680-3P | 30-280 | 16"(400) | 1 No | 3P | AC | 415 | 50 | 0.47 | 60 | 17,500 | 25-40 | 520x640x320 |

| EFP-H-1890-1P | 30-300 | 18"(450) | 1 No | 1P | AC | 230 | 50 | 1.2 | 79 | 20,833 | 30-50 | 650x800x380 |

| EFP-H-1890-3P | 30-300 | 18"(450) | 1 No | 3P | AC | 415 | 50 | 0.6 | 79 | 20,833 | 30-50 | 650x800x380 |

| EFP-H-1890-T | 30-300 | 18"(450) | 1 No | 3P | AC | 415 | 50 | 0.6 | 83 | Ask Drawing | Ask Drawing | Ask Drawing |

| EFP-H-2432 | 30-300 | 24” (600) | 1 No | 3P | AC | 415 | 50 | 3.3 | 85 | Ask Drawing | Ask Drawing | Ask Drawing |

| EFP-H-2583 | 30-350 | 25”(625) | 1 No | 3P | AC | 415 | 50 | 405 | 83 | Ask Drawing | Ask Drawing | Ask Drawing |

| EFP-H-3044 | 25-400 | 30” (750) | 1 No | 3P | AC | 415 | 50 | 407 | 83 | Ask Drawing | Ask Drawing | Ask Drawing |

| EFP-H-3650 | 30-400 | 36”(900) | 1 No | 3P | AC | 415 | 50 | 11.25 | 86 | Ask Drawing | Ask Drawing | Ask Drawing |

| EFP-H-3655 | 30-400 | 36”(900) | 1 No | 3P | AC | 415 | 50 | 5.5 | 90 | Ask Drawing | Ask Drawing | Ask Drawing |

Installation Guidelines for Air-Cooled Oil Cooler

Air-cooled oil coolers are commonly used in machinery and vehicles to regulate the temperature of the oil, ensuring efficient performance and prolonging the life of components. The installation of an air-cooled oil cooler must be done correctly to maximize its efficiency and prevent any operational issues. Below are the detailed steps and technical considerations for installing an air-cooled oil cooler.

Pre-Installation Preparation:

- Check Oil Cooler Specifications: Ensure the cooler matches the required specifications for the application (e.g., pressure rating, flow rate, temperature range).

Tools and Materials Needed

- Wrenches, screwdrivers, and spanners

- Gaskets and seals (if necessary)

- Hose, fittings, clamps, and fasteners

- Mounting brackets and bolts

- Oil cooler mounting kit (if applicable)

Safety Precautions: Before starting, ensure the system is de-energized, and no pressure is present in the system. Wear protective gear to avoid injury.

Selecting the Installation Location

Ambient Air Flow: The location must allow sufficient airflow to the cooler. Typically, the cooler should be placed in an area where air can flow freely, such as near a fan or open spaces on the equipment.

Accessibility for Maintenance: Ensure the cooler is accessible for regular maintenance, cleaning, and inspection.

Vibration Considerations: The installation location should minimize vibration to prevent stress on the cooler and associated components.

Mounting the Oil Cooler

Mounting Brackets

- Use the appropriate mounting brackets for the cooler Ensure they are securely fastened to the frame or structure.

- Mount the cooler in a vertical or horizontal position as per manufacturer recommendations. The vertical position generally provides better airflow.

Ensure Proper Alignment: Check that the cooler is aligned with the oil lines to avoid strain or bending of the hoses.

Connecting the Oil Lines

Inlet and Outlet Connections

- Identify the inlet and outlet ports on the oil cooler. Ensure that the oil flows through the cooler in the proper direction as per the design (check for arrows or

- labels).

- The oil inlet should be connected to the source of hot oil, while the outlet should direct the cooled oil back to the system.

Use High-Quality Hoses: Use hoses rated for the temperature and pressure requirements of the oil system.

- Secure the hoses with proper clamps to prevent leaks or disconnections. Tighten all fittings, but avoid over-tightening.

Correct Flow Rate: Ensure the oil flow rate is compatible with the cooler. An excessively high flow rate can reduce cooling efficiency, while too low a flow rate can cause overheating

Ventilation and Airflow

Ensure Proper Ventilation: The oil cooler should be placed in a location with good air circulation. If necessary, install fans to improve air flow over the cooler's surface.

Minimize Obstructions: Ensure that there are no obstructions blocking the air intake or exhaust around the cooler.

Pressure Testing

Check for Leaks: Before starting the system, pressurize the oil cooler and connections to ensure there are no leaks.

Test the Oil Flow: Check the oil flow rate and temperature to ensure that the cooler is operating within its designed parameters.

Monitor System Pressure: Ensure that the oil pressure is maintained within the required limits.

Post-Installation Checks

Start the System: After installation, start the system and check the oil temperature to ensure the cooler is working properly

Observe for Leaks: Inspect all connections for leaks, and tighten fittings as necessary.

Monitor Performance: Check the oil temperature regularly to ensure that the cooler is effectively maintaining the correct operating temperature.

Technical Details to Consider

Heat Transfer Capacity: The heat transfer capacity of the oil cooler is determined by the size of the cooler, the flow rate of the oil, and the air flow over the cooler. Ensure the cooler is properly sized for the application.

Material Construction: Air-cooled oil coolers are typically made from materials such as aluminium or steel, with aluminum being more common due to its lighter weight and better heat dissipation properties.

Operating Pressure: The cooler should be able to handle the system’s pressure, typically in the range of 5-10 bar, but higher pressures may require stronger materials.

Temperature Rating: Check the oil cooler's temperature rating, which is often in the range of 90°C to 150°C (194°F to 302°F). The cooler must be able to handle the system's oil temperature under all operating conditions.

Airflow: The air cooler’s efficiency depends on airflow. Larger coolers with greater surface areas dissipate more heat but require more air flow. Ensure that the cooler is installed where sufficient air can pass over its surface, either naturally or with the assistance of a fan.

Filtration: If applicable, install an oil Filter before the oil enters the cooler to remove contaminants that may clog the cooler.

Maintenance Tips:

Regular Cleaning: Periodically clean the air cooler's Fins or external surface to ensure efficient heat exchange. Dust and dirt can accumulate, reducing airflow and cooling efficiency.

Check for Blockages: Inspect the inlet and outlet ports regularly to ensure there are no blockages that could affect oil flow.

Inspect Hoses and Fittings: Regularly check the hoses and fittings for signs of wear, leaks, or corrosion.

By following these guidelines and ensuring that the cooler is installed in the proper location with correct air flow and oil flow, the air-cooled oil cooler will function efficiently and effectively.

Register Now to claim your Additional Benefits.

- Extended Warranty

- Installation Guidelines

- Additional Discounts

- Festival Offers

- New Product Launches and Much More

Choose Your Air Cooled Oil Cooler Model Number Drawings for all Models

Applications

Air-cooled oil coolers and fluid coolers with fans are widely used in various industrial applications where efficient heat dissipation is required. Below are some of the key applications:

Automotive and Transportation Industry

Engine Cooling: In vehicles, air-cooled oil coolers are used to manage engine oil temperatures, ensuring that the engine operates within its optimal temperature range.

Transmission Cooling: For automatic transmissions, air-cooled coolers help maintain fluid temperatures,

preventing overheating and ensuring smooth gear shifting.