Hydraulic Cylinders Manufacturers in Delhi

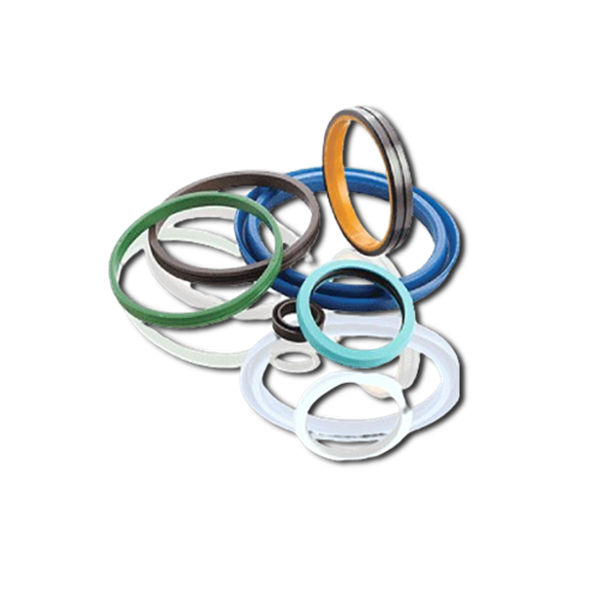

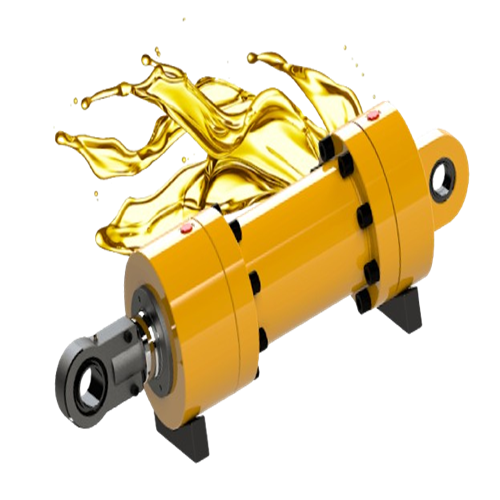

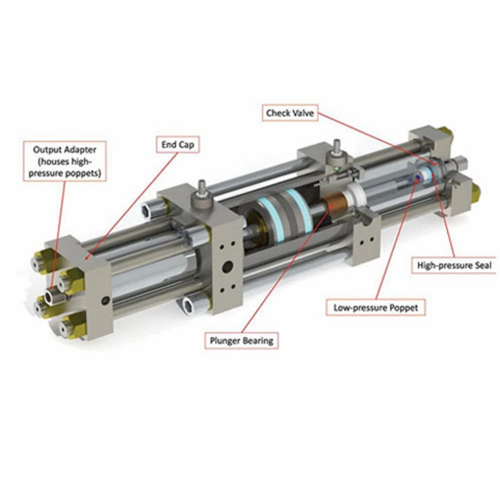

Erika Fluid Power is the best Hydraulic cylinder Manufacturer in New Delhi. Our hydraulic cylinders are made using the most reliable and quality raw materials, which then ensures that there is durability and long service life for our products as well. These cylinders are made to work at high pressure under rigors of work, thus amongst others fitting for challenging applications. The cylinders we make include advanced sealing technology that eliminates fluid leakage and assures dependable operations. Such seals are made with quality materials to provide wear resistance and assure a long-lasting solution against fluid leakage.

Hydraulic cylinder Exporters from Delhi

We are the punctual Hydraulic cylinder Exporters from Delhi. The High-pressure resistance in our hydraulic cylinders is made to perform even in the most demanding environments. Thus, this makes them very ideal for those heavy-duty applications that require maximum force. Our treated corrosion-resistant coatings offer improved cylinder life, enabling them to bear up in harsh environments and go on performing efficiently over time.

Hydraulic Cylinders Suppliers in India

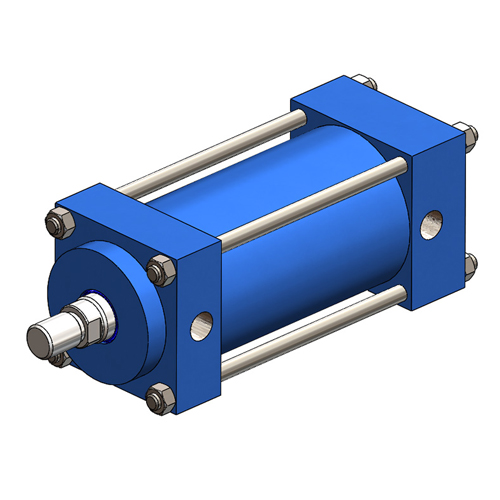

Consider us for all the needs of your Hydraulic Cylinders Wholesale Suppliers in India. Since we do not compromise on quality and precision, you can be assured of the reliability of our hydraulic cylinders. They will serve you with predictable good performance without the need for frequent maintenance and repairs. Durability and longevity in service life lower the overall cost for your business. This reduces the frequency of replacements and subsequent repairs, saving money in the long term. Our cylinders are designed to make maintenance easy, with all components readily accessible and flexible, with simple servicing procedures that help you keep maintenance costs as low as possible while allowing any required repair work to be completed efficiently and effectively.

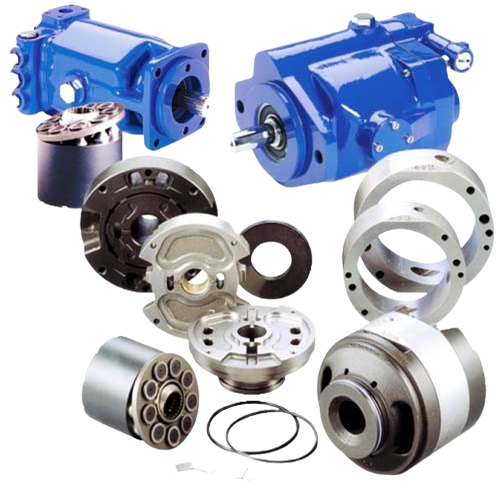

A hydraulic cylinder is a mechanical actuator that converts hydraulic energy into linear motion. It’s a crucial component in various hydraulic systems, providing the force needed to drive machinery and equipment.

Types of Hydraulic Cylinders:

- Single-Acting Cylinder Function: Applies force in one direction only, usually by hydraulic pressure on one side of the piston. The return stroke is typically achieved by a spring or gravity.

- Double-Acting Cylinder Function: Applies force in both directions, with hydraulic pressure on both sides of the piston allowing for controlled movement in both directions.

- Tie-Rod Cylinder Function: Uses external tie rods to hold the cylinder barrel and end caps together. It’s designed for durability and ease of maintenance.

- Telescopic Cylinder Function: Consists of multiple nested cylinders that extend sequentially to provide a long stroke length in a compact form.

Operating Principles:-

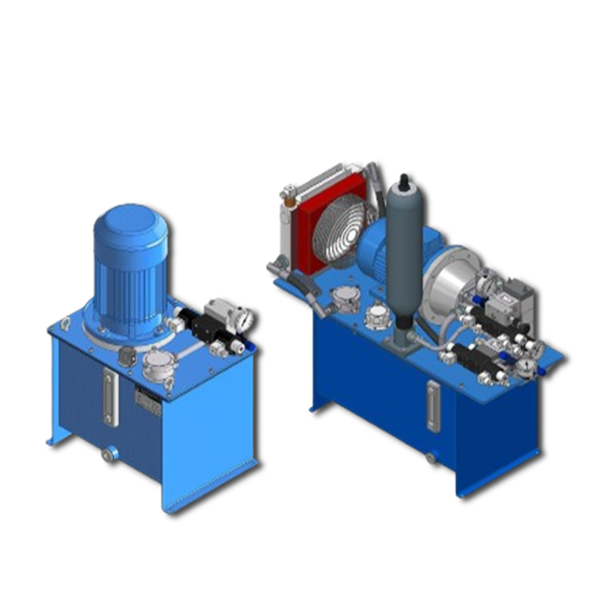

- Hydraulic Fluid Pressure: Hydraulic fluid is pumped into the cylinder, creating pressure that forces the piston to move. The movement of the piston extends or retracts the rod, providing linear motion.

- Sealing: High-quality seals prevent hydraulic fluid leakage and protect the internal components from contaminants, ensuring smooth operation and longevity.

- Force and Stroke Length: The force exerted by the cylinder is determined by the pressure of the hydraulic fluid and the surface area of the piston. The stroke length is the distance the piston can travel within the cylinder.

| S.No | Technical Specification | Description |

| 1 | Bore Diameter | 25 mm (1 in) To 1,200 mm (47 in) |

| 2 | Rod Diameter | 10 mm (0.4 in) To 600 mm (24 in) |

| 3 | Stroke Length | 25 mm (1 in) To 12,000 mm (472 in) or more (special designs can exceed this) |

| 4 | Maximum Operating Pressure | 50 bar (725 psi) To 700 bar (10,000 psi) or more (special high-pressure cylinders can exceed this) |

| 5 | Maximum Force Output | 1,000 kN (225,000 lbf) or more, depending on the size and design |

| 6 | Cylinder Type | Single-acting, double-acting, tie-rod, welded, and telescopic |

| 7 | Cylinder Length | 100 mm (4 in) TO 15,000 mm (590 in) or more, depending on design and application |

| 8 | Temperature Range | 40°C (-40°F) 200°C (392°F) or more (with special materials and designs) |

| 9 | Mounting Styles | Flange mount, trunnion mount, foot mount, clevis mount Custom mounts for specific applications or environments |

| 10 | Cylinder Design Pressure | 10 bar (145 psi) TO 1,200 bar (17,400 psi) or higher for specialized high-pressure cylinders |

| 11 | Materials | MS, High-strength steel, stainless steel, or custom alloys for corrosive or high-pressure |

| 12 | Certification and Standards | Certifications for specific industries (e.g., API, CE, ASME ISO) |

Applications:-

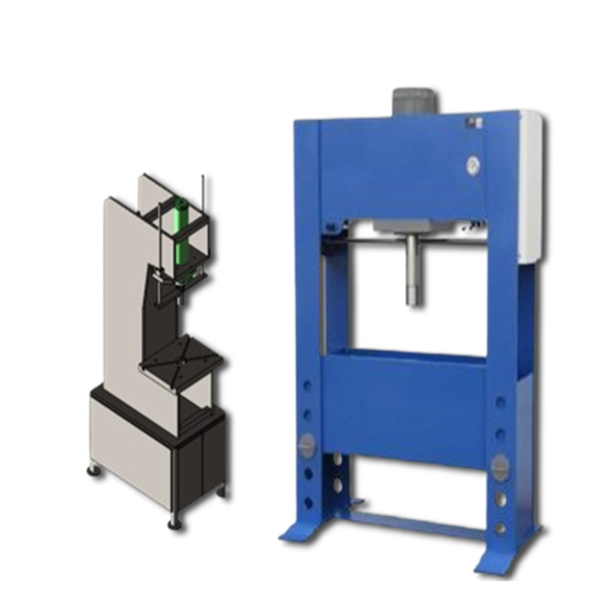

- Industrial: Presses, lifts, automation.

- Construction: Excavators, loaders, cranes.

- Automotive: Lifts, jacks, suspension systems.

- Agricultural: Tractors, harvesters.

- Marine: Deck machinery, steering systems.

- Aerospace: Actuation systems, landing gear.

- These specifications can vary based on the manufacturer and specific design requirements. For precise needs, consulting technical datasheets from manufacturers and custom engineering services is recommended.