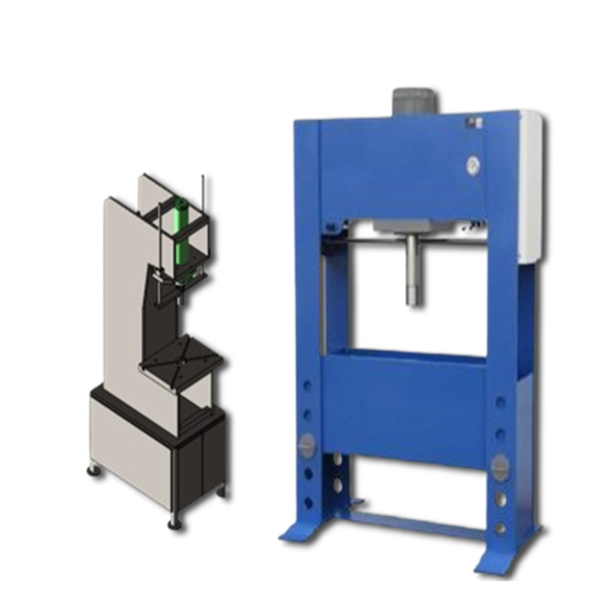

Hydraulic Power Pack Manufacturers in Delhi

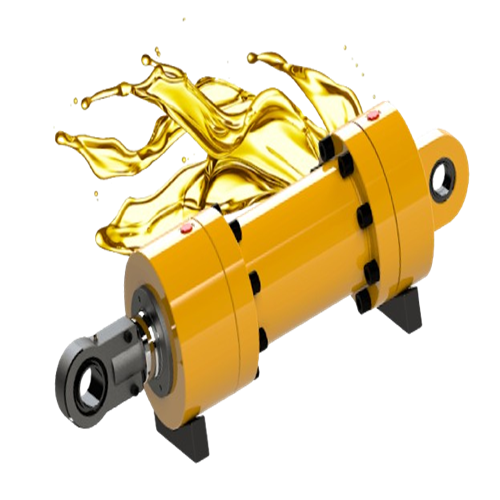

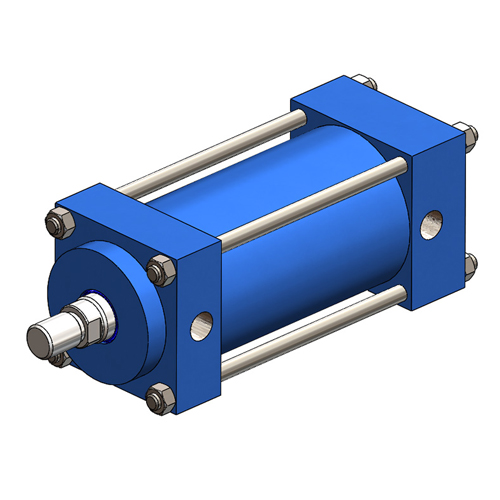

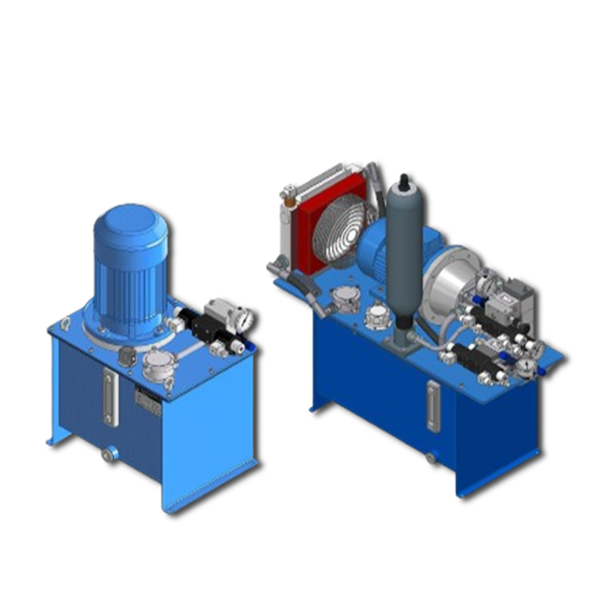

Erika Fluid Power is the best Hydraulic Power Pack Manufacturers in New Delhi. The Hydraulic Power Pack that we make is specifically designed to give very high energy efficiency to ensure that your equipment runs at its best level. This high efficiency that you get with our AMD power pack helps in saving energy and thus a reduction in operating costs. All of our power packs are designed for easy maintenance, where components are easily accessible and servicing procedures are simple to follow. This cuts downtime and long-term maintenance costs, keeping your operation flowing smoothly.

Hydraulic Power Pack Exporters from Delhi

We are the punctual Hydraulic Power Pack Exporters from Delhi. Our power packs come with advanced sealing technology, which leak-proofs them and avoids any kind of contamination of the inner components. This improves durability and assures reliable performance. All of our power packs are designed to be quiet and so reduce noise in your work environment, making them more comfortable to use continuously and maintaining a quieter workspace. This then delivers consistent, dependable power to your equipment, our hydraulic power packs make it work better and faster. They speed up productivity and let you finish the job sooner.

Hydraulic Power Pack Suppliers in India

Consider us for all the needs of your Hydraulic Power Pack Wholesale Suppliers in India. Our strong, leak-tight constructions with our power packs reduce maintenance. Less downtime coupled with reduced maintenance translates to continuous operation with less cost incurred. Our corresponding power packs resist, even in the toughest conditions of use. This resistance to harsh working conditions secures your investment in giving back reliable performance over several years. Our power packs' quiet operation maintains a comfortable and quieter workspace, good for the entire atmosphere when working.

Hydraulic power packs are used in various industries and applications where hydraulic power is required to drive machinery and equipment. Here’s an overview of their applications:

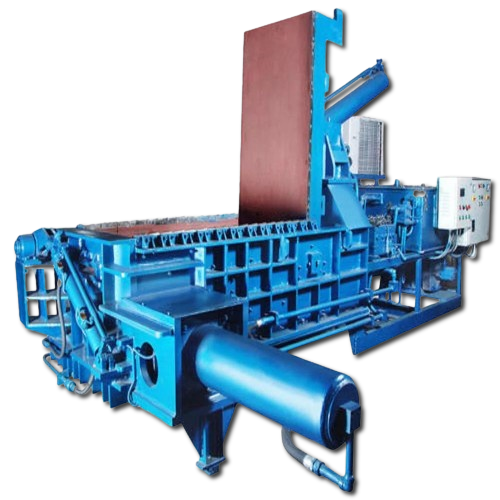

- Industrial Machinery: Operating hydraulic presses, injection molding machines, and machine tools.

- Construction: Powering hydraulic systems in construction equipment and tools.

- Manufacturing: Driving hydraulic systems in production lines and manufacturing processes.

- Mobile Equipment: Providing hydraulic power to vehicles and equipment used in agriculture, forestry, and mining.

- Marine and Offshore: Powering hydraulic systems on ships and offshore platforms.

- Aerospace: Providing hydraulic power for various aerospace systems and ground support equipment.

Key Considerations for Applications:

- Power Requirements: Ensure the power pack can meet the hydraulic power needs of the application.

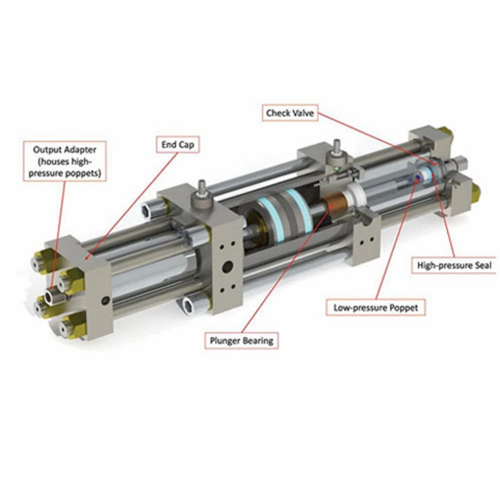

- Pressure and Flow Rates: Select components that match the required pressure and flow rates for optimal performance.

- Environmental Conditions: Consider factors like temperature, humidity, and exposure to elements when selecting and configuring the power pack.

- Maintenance and Reliability: Choose a design that allows for easy maintenance and has a reputation for reliability in the intended application.

- Hydraulic power packs are essential for providing reliable and efficient hydraulic power across a broad range of industries and applications.

| Sr No | Technical Specification | Description |

| 1 | Reservoir Capacity | 10 L (2.6 gal) to 10,000 L (2,641 gal) |

| 2 | Motor Power | 0.5 kW (0.7 hp) to 500 kW (670 hp) |

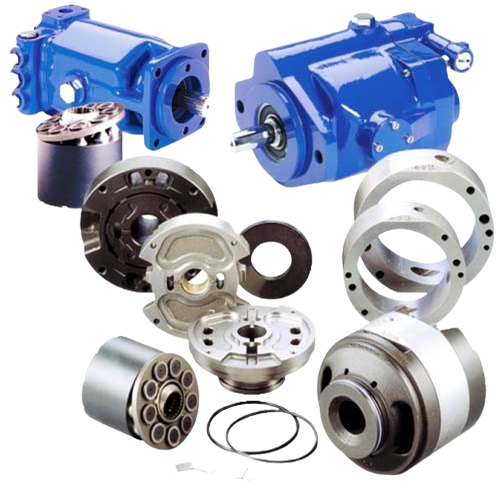

| 3 | Pump Type | Gear pumps, vane pumps, Axial piston pump, Radial piston pump |

| 4 | Flow Rate | 0.5 L/min (0.13 gal/min) to 500 L/min (132 gal/min) |

| 5 | Pressure Rating | 50 bar (725 psi) to 700 bar (10,000 psi) |

| 6 | Motor Type | Electric, diesel, or gas engine, Single-phase electric motor |

| 7 | Temperature Range | 20°C (-4°F) to 100°C (212°F) (depending on fluid and design) |

| 8 | Temperature Range | Basic filters with a 10 µm (micron) rating to High-efficiency filters with < 1 µm rating, multi-stage filtration |

| 9 | Size and Weight | Compact units ~0.5 m³ (17.7 ft³) and ~50 kg (110 lbs) to Large units ~50 m³ (1,766 ft³) and ~10,000 kg (22,046 lbs) |

| 10 | Hydraulic Fluid | Mineral oil, water-based fluids, or special fluids to Specialized fluids (e.g., fire-resistant or biodegradable) |

| 11 | Control Options | Manual controls, Automated controls with PLC (Programmable Logic Controller) integration |

| 12 | Noise Level | 60 dB(A) (quiet operation) 100 dB(A) (high noise levels, usually with larger units |

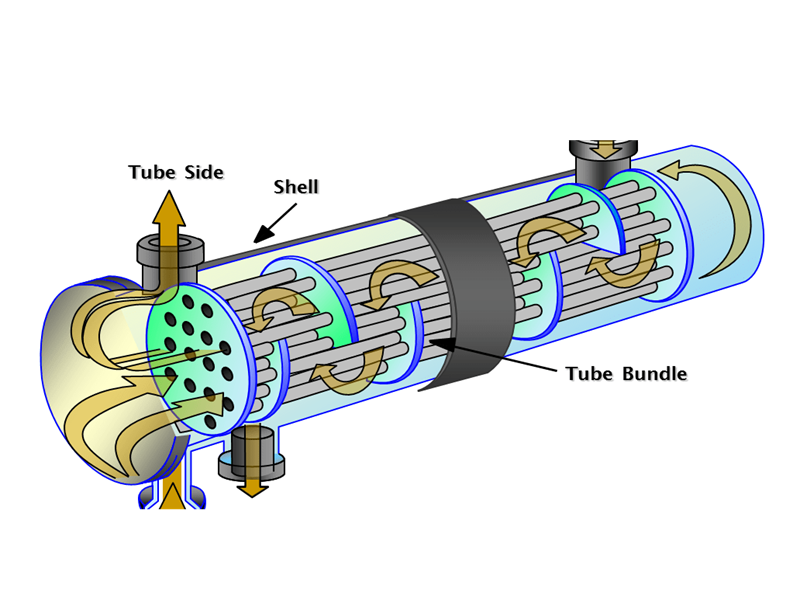

| 13 | Cooling System | Air-cooled or water-cooled to Advanced water-cooled or oil-to-water heat exchangers |

| 14 | Safety Features | Basic pressure relief valves and temperature sensors and Advanced safety systems with multiple redundancy, emergency shut-off, and monitoring systems |

| 15 | Standards and Certification | Basic compliance with industry standards to Certifications such as ISO, CE, and API |

| 16 | Mounting and Configuration | Simple base frame Custom mounts, skid-mounted units, or trailer-mounted units for mobility |

| 17 | Integration | Basic connections for hydraulic hoses and Complex integration with existing machinery, including custom manifolds and control systems |