Hydraulic Manifold Block Manufacturers in Delhi

Erika Fluid Power is the best Hydraulic Manifold Block Manufacturers in New Delhi. We have used steel, aluminum, or cast iron in the making of our hydraulic manifold block which means that these will last for years to come. The materials used in its construction are made for good durability, high-pressure resistance, and working condition endurance to sustain their performance over time. Our manifold blocks have compact designs that make efficient use of space within the hydraulic system. This compactness helps to reduce the overall size and weight of the hydraulic setup; this often proves very useful where space is limited.

Hydraulic Manifold Block Exporters from Delhi

We are the punctual Hydraulic Manifold Block Exporters from Delhi. Manifold blocks we make are specifically designed by us to optimize the fluid flow, this then decreases the turbulence and enables that there are smooth operations in play. With the help of our blocks, you can have proper flow management and this will, in turn, reduce the energy loss that is caused, thus enhancing the overall efficiency of the hydraulic system. We have applied a heavy coating that prevents rusting and corrosion caused by moisture or chemicals in the surrounding air, thus increasing the life of the blocks.

Hydraulic Manifold Block Suppliers in India

Consider us for all the needs of your Hydraulic Manifold Block Wholesale Suppliers in India. Design can be easier with fewer hoses and fittings in your hydraulic system using our manifold blocks. This consolidation results in a neater, much more organized system that is far easier to handle throughout its life cycle. Leak potential is drastically reduced due to precise machining and quality materials throughout the manifold block. Not only will this improve the reliability of your hydraulic system, but it will also reduce environmental impacts coming from the spilled hydraulic fluid.

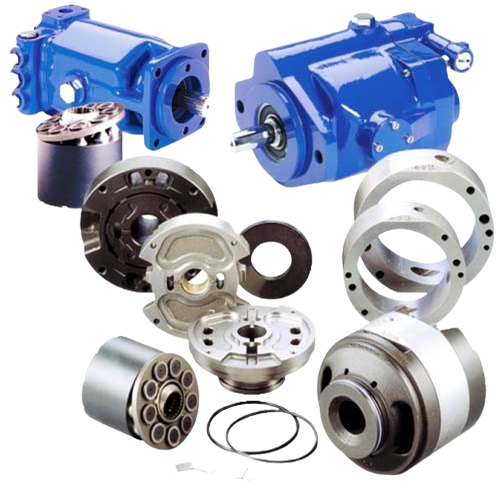

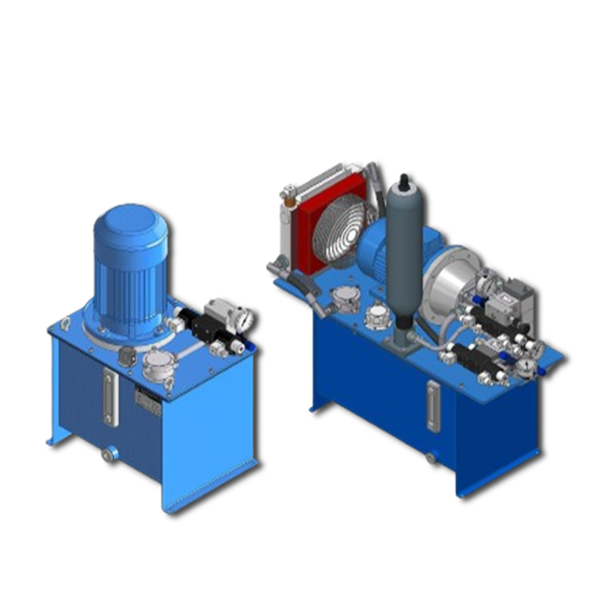

A hydraulic manifold block is a crucial component in hydraulic systems, used to manage and direct hydraulic fluid flow. It acts as a central hub for connecting various hydraulic components such as pumps, valves, actuators, and motors. Here’s a detailed look at hydraulic manifold blocks:

Function and Purpose:-

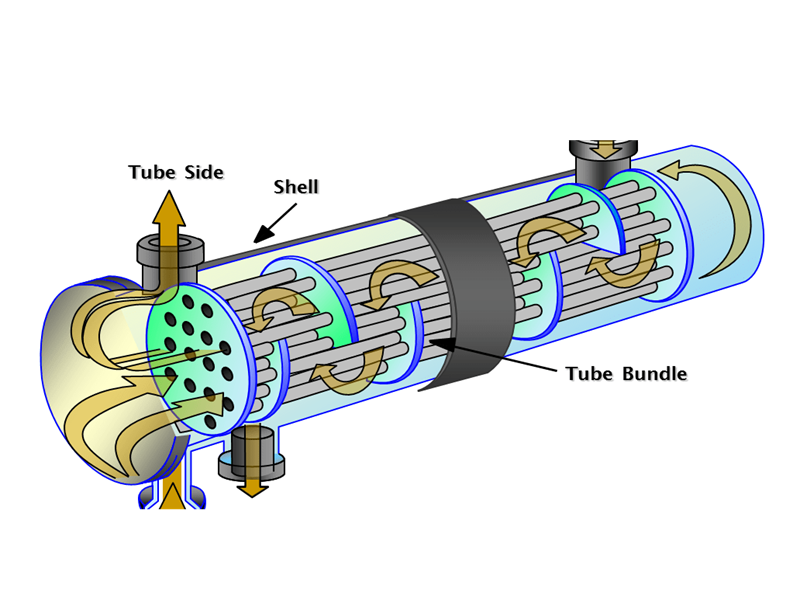

Fluid Distribution: Manifold blocks distribute hydraulic fluid to different parts of the system. They consolidate multiple fluid lines into a single block, reducing the complexity and potential leak points of a hydraulic system.

Integration: They integrate multiple hydraulic functions (such as pressure control, flow control, and directional control) into one compact unit, which can simplify the hydraulic system design and reduce space requirements.

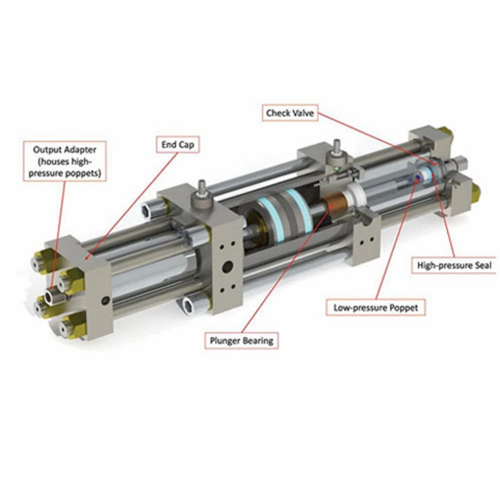

Control: Manifold blocks often house various control valves, including pressure relief valves, check valves, and directional control valves, allowing precise control over hydraulic functions.

Pressure Management: They can include pressure-regulating components to manage and maintain consistent pressure throughout the system.

Design Considerations:-

Material: Manifold blocks are typically made from materials such as aluminum, steel, or stainless steel. The choice of material depends on factors like pressure rating, fluid type, and environmental conditions.

Size and Configuration: The size and configuration of a manifold block are determined by the number of ports and the complexity of the hydraulic circuit. Custom designs are often used to meet specific application requirements.

Pressure Rating: The manifold block must be designed to handle the maximum pressure of the hydraulic system. This includes considering the strength of the material and the design of internal passages.

Flow Capacity: The flow capacity of the manifold block must match the flow requirements of the hydraulic system to ensure efficient operation and avoid flow restrictions.

Leakage Prevention: Proper sealing and machining are essential to prevent leaks and ensure reliable operation. O-rings and seals are used to maintain pressure and fluid containment.

Applications:-

- Industrial Machinery: In hydraulic presses, injection molding machines, and other heavy machinery.

- Mobile Equipment: Such as excavators, loaders, and agricultural equipment.

- Aerospace: For controlling hydraulic systems in aircraft.

- Automotive: In hydraulic braking systems, steering systems, and other vehicle applications.