Hydraulic Clamp Cylinder Manufacturers in Delhi

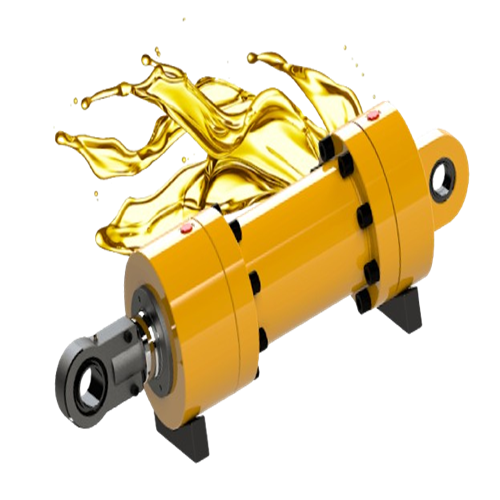

Erika Fluid Power is the best Hydraulic Clamp Cylinder Manufacturers in New Delhi. Hydraulic Clamp Cylinders are super cost-effective in the long run as a result of their low maintenance cost and robust structure, it even drastically reduces the chances of downtime. Less time out of operation by quick procedures for maintenance coupled with reliable performance assures top uptime and productivity for machines.

Hydraulic Clamp Cylinder Exporters from Delhi

We are the punctual Hydraulic Clamp Cylinder Exporters from Delhi. The accuracy and reliability of our hydraulic clamp cylinder thus become very important to businesses that value quality. Constant clamping force secures uniformity in production most essential for maintaining high standards in the quality area and meeting customer expectations. Our Hydraulic Clamp Cylinder accomplishes improved productivity with predictable and consistent clamping force. Operators are assured of the security of their workpieces—this guarantees faster and more efficient machining/assembly techniques. This reliability reduces the need for rework and increases overall production.

Hydraulic Clamp Cylinder Suppliers in India

Consider us for all the needs of your Hydraulic Clamp Cylinder Wholesale Suppliers in India. Our Hydraulic Clamp Cylinder runs smoothly, reducing wear on the cylinder and the workpiece. The quality of the seal and precision machining would thus effectively reduce high friction to ensure minimal wear out over time for continuous performance. With our hydraulic clamp cylinder, clamping force is great; hence, it will hold large and heavy workpieces. This high clamping force is essential for tasks that require a secure hold to restrict movement during machining or assembly processes.

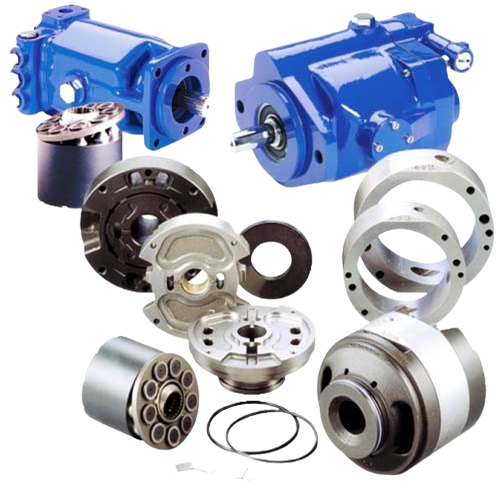

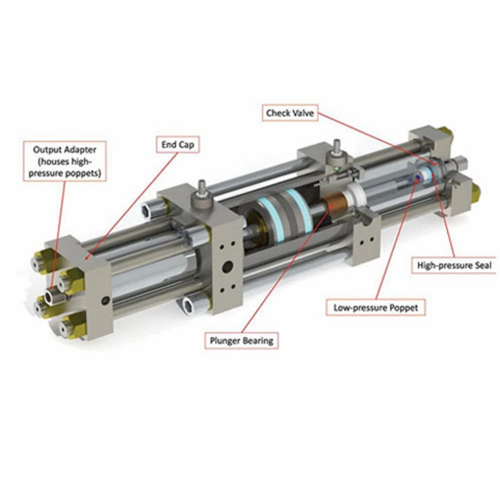

Components and Operation:

- Cylinder Barrel: The main body of the cylinder where the hydraulic fluid is contained.

- Piston: Inside the barrel, this component moves back and forth in response to hydraulic pressure, creating the clamping force.

- Rod: Attached to the piston, it extends or retracts to apply or release the clamping force.

- End Caps: These seal the ends of the barrel and usually include ports for hydraulic fluid.

- Hydraulic Fluid: This pressurized liquid powers the movement of the piston

Technical Specifications for Hydraulic Clamp Cylinders:-

- Bore Diameter:25 mm (1 inch) Up to 300 mm (12 inches) or more

- Stroke Length:50 mm (2 inches) Up to 1000 mm (40 inches), depending on application

- Rod Diameter:10 mm (0.4 inches) Up to 150 mm (6 inches)

- Operating Pressure: 70 bar (1,000 psi) Up to 700 bar (10,000 psi) or higher

- Clamping Force: 1 kN (kilonewton) or 220 lbf (pound-force) Up to 500 kN (112,000 lbf)

- Operating Temperature : -20°C (-4°F) Up to 80°C (176°F) or higher,

- Port Sizes: 1/8 inch BSP Up to 2 inches BSP or NPT

- Mounting Types: Front flange, rear flange, tie-rod, or trunnion mount or Custom mounts

Technical Specification:-

- Bore Size: 8 mm or 0.3 inches up to 500 mm or 20 inches

- Cylinder Rod Diameter: 8 mm or 0.3 inches Up to 100 mm or 4 inches

- Stroke Length: 10 mm or 0.4 inches Up to 6,000 mm or 236 inches

- Pressure Rating: 0.1 MPa or 1 bar (14.5 psi) Up to 1.0 MPa or 10 bar (145 psi)

- Operating Temperature Range: -40°C or -40°F Up to 80°C or 176°F

- Mounting Type: Basic tie rod or single-flange mounting Custom or complex mounting systems including pivot, foot, and multiple flange options

- Cycle Life: 1 million cycles Up to 100 million cycles for high-duty

- Port Size and Type: 1/8 inch (NPT or BSP) or 4 mm push-to-connect Up to 1 inch (NPT or BSP) or 12 mm push-to-connect

- Force Output: 10 N or 2.2 lbf Up to 10,000 N or 2,250 lbf.