Pneumatic Cylinder Manufacturers in Delhi

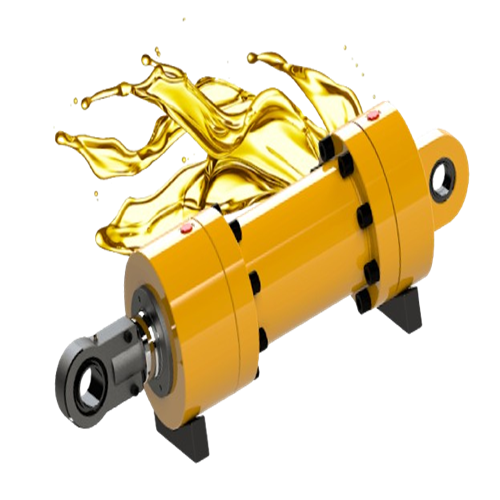

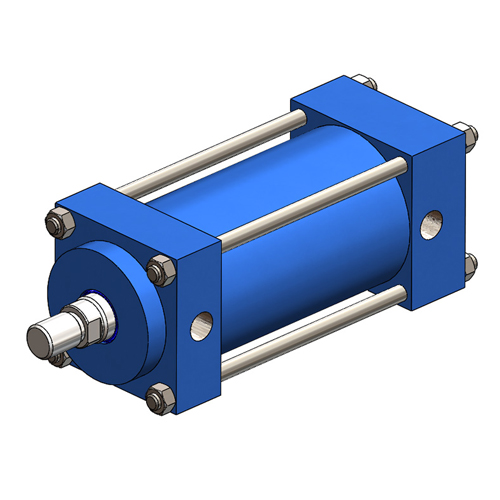

Erika Fluid Power is the best Pneumatic Cylinder Manufacturers in New Delhi. Want to have the most advanced and dependable Pneumatic Cylinder? Well, you are at the right place. With advanced capabilities and features. The pneumatic cylinders that we make are important when it comes to effectively drawing the compressed air. Advanced systems of air management and additional optimized internal designs minimize air absorption and, as a result, ensure reducing operating costs about developing the general efficiency.

Pneumatic Cylinder Exporters from Delhi

We are the punctual Pneumatic Cylinder Exporters from Delhi. All the interior components are made using the Pneumatic Cylinder that comes with high precision to provide a perfectly smooth and frictionless movement, thereby giving equal performance every time and reducing the wear of the cylinder and other components in the system. Our pneumatic cylinders find extensive applications in robotics and automation industries for picking, placing, and relocating objects. Precise control and reliable performance make them especially suitable for high-speed and repetitive operations.

Pneumatic Cylinder Suppliers in India

Consider us for all the needs of your Pneumatic Cylinder Wholesale Suppliers in India. These pneumatic cylinders we make become an integral part of such industries as packaging and material handling for sealing, cutting, and sorting. The packaging procedures become very accurate and reliable with their smooth motion. They also find applications in the automotive industry, where they control the motion of machine tools, handle auto parts, and run machinery at assembly lines. They contribute to efficient and precise production processes in the automobile industry. Our pneumatic cylinders are designed in conformance with the hygiene and safety standards set by the food and beverage industry. Our cylinders are used in filling, capping, and labeling processes, among others. The hygienic and uncontaminated feature of the system ensures flawless performance in these processes.

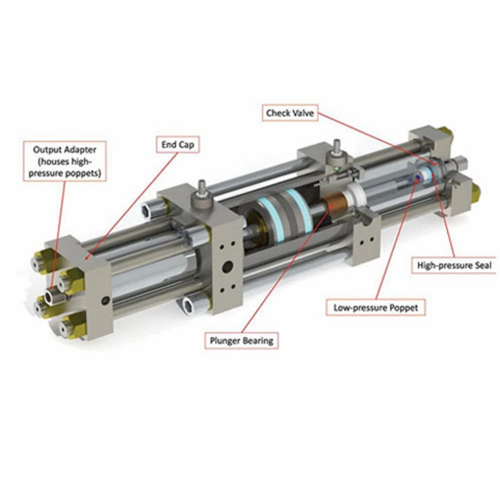

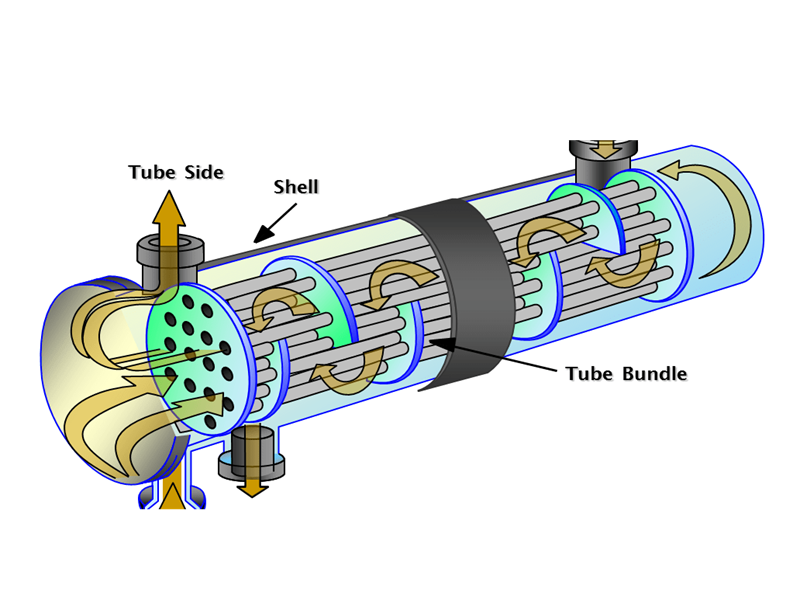

A pneumatic cylinder is a device that uses compressed air to produce mechanical movement. It converts the energy from compressed air into linear motion, making it a crucial component in many automation and manufacturing systems. Here's a basic overview of its key components and functionality:

- Cylinder Barrel: The main body of the cylinder, which houses the internal components and provides a space for the piston to move.

- Piston: The internal component that moves back and forth within the cylinder barrel. It is connected to a rod that extends out of the cylinder to do work.

- Rod: The part that extends out of the cylinder and is connected to the piston. It transfers the mechanical force generated by the piston to the external system.

- End Caps: These are fitted at each end of the cylinder barrel and contain the seals that prevent the compressed air from escaping.

- Seals: These prevent air from leaking out of the cylinder and help maintain pressure and performance.

- Ports: Inlets and outlets for the compressed air to enter and exit the cylinder.