Hydraulic Baling Press Manufacturers in Delhi

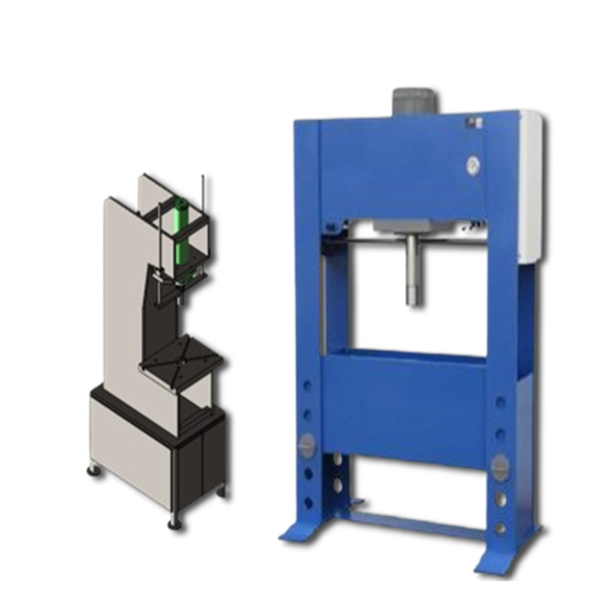

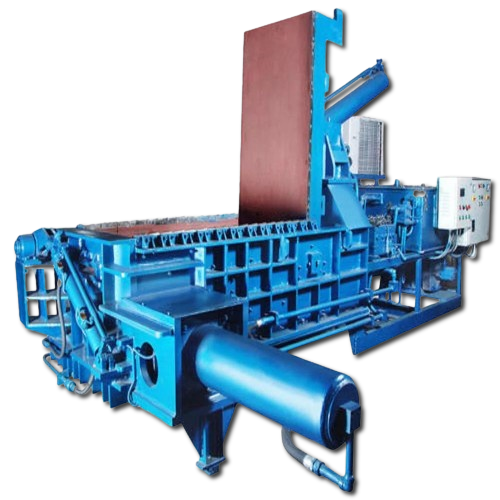

Erika Fluid Power is the best Hydraulic Bailing Press Manufacturers in New Delhi. Investing in our Baling Presses can be super reliable and healthy for your business. As the Machines are durable, high-performance, energy-efficient, and low maintenance provide the best value for money to customers. Our Machines save Operational costs, decrease expenses related to waste management, and increase the efficiency of operations for long-term Savings.

Hydraulic Bailing Press Exporters from Delhi

We are the punctual Hydraulic Bailing Press Exporters from Delhi. The baling presses demand high performance, and we understand it very well that is why our machines are meant to deliver this high performance without fail. They can quickly produce dense and uniform bales, making any waste management process efficient and effective. The high performance of our Baling Presses keeps you going with the high-volume productions in waste generation without a hitch. The Baling Presses that we make are suitable for various industries, hence helpful in manufacturing, recycling, and waste management. Hence with our bailing press, you can handle several different materials simplifying your operations and the need to have multiple pieces of equipment.

Hydraulic Bailing Press Suppliers in India

Consider us for all the needs of your Hydraulic Bailing Press wholesale suppliers in India. Our Baling Presses are rugged and resilient. Steel built, they have high-quality material construction, which will sustain heavy use in any tough, industrial environment. Their strong build provides years of reliable performance from a range of our machines. Durability reduces your costs due to less downtime and maintenance; hence, you give yourself a reliable solution for handling waste management.

A scrap bailing press is a specialized type of industrial equipment used primarily in the recycling industry. Its main function is to compress various types of scrap materials—such as paper, cardboard, plastics, metals, and textiles—into dense, manageable bales. These bales are easier to handle, store, and transport compared to loose scrap.

Key Features and Functions:-

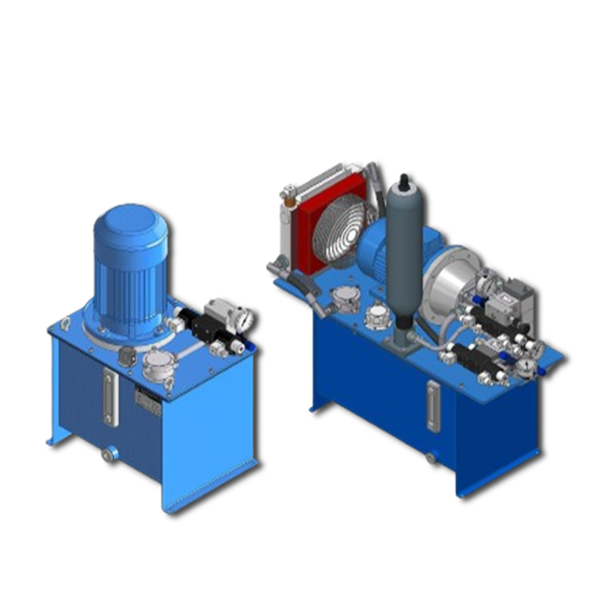

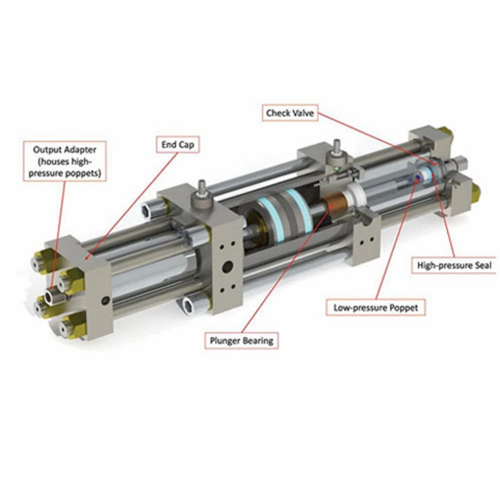

- Compression: The press uses hydraulic or mechanical systems to compress scrap materials into bales. The compression helps reduce the volume of waste, making it more efficient for transportation and processing.

- Bale Size and Density: Scrap bailing presses can often be adjusted to produce bales of different sizes and densities, depending on the type of material and the requirements of the recycling facility.

- Automated Operations: Many modern bailing presses are automated to improve efficiency and reduce labor costs. They may include features like automatic feeding systems, programmable controls, and safety mechanisms.

- Material Handling: Some models come with conveyors or shredders to help prepare and feed the scrap material into the press.

- Durability: Given the tough nature of recycling materials, these presses are built to be durable and handle heavy loads and continuous use.

Technical Specification:-

- Bale Dimensions: 18" x 24" x 36" (45 cm x 60 cm x 90 cm) to 30" x 30" x 48" (75 cm x 75 cm x 120 cm) or more.

- Bale Weight: 20 to 50 pounds (9 to 23 kg) to 100 to 300 pounds (45 to 136 kg) or more

- Material Processed: Up to 1,000 pounds per hour (450 kg/h) to Up to 2,000 to 4,000 pounds per hour (900 to 1,800 kg/h) depending on the model and material type

- Hydraulic Pressure:1,000 to 2,000 psi (70 to 140 bar) up to 2,500 to 3,000 psi (175 to 210 bar)

- Motor Size: 2 to 5 horsepower (HP) (1.5 to 3.7 kW) up to 10 to 20 horsepower (HP) (7.5 to 15 kW) or more

- Dimensions: Typically around 5 to 7 feet tall (1.5 to 2.1 meters) and 3 to 4 feet wide (0.9 to 1.2 meters) up To 7 to 10 feet tall (2.1 to 3 meters) and 4 to 6 feet wide (1.2 to 1.8 meters)

- Space Requirement: Approximately 10 to 15 sft up to 30 to 50 square feet