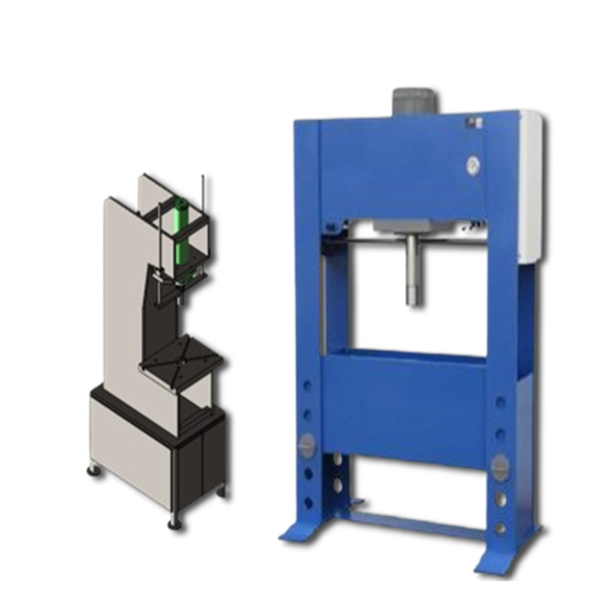

Hydraulic Pump Manufacturers in Delhi

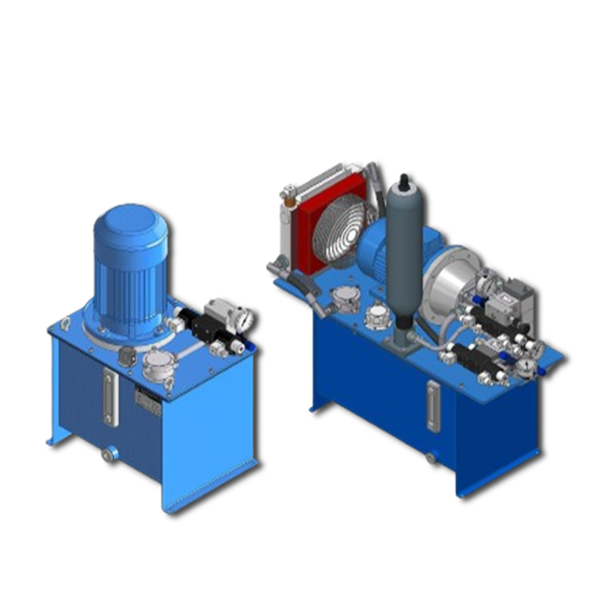

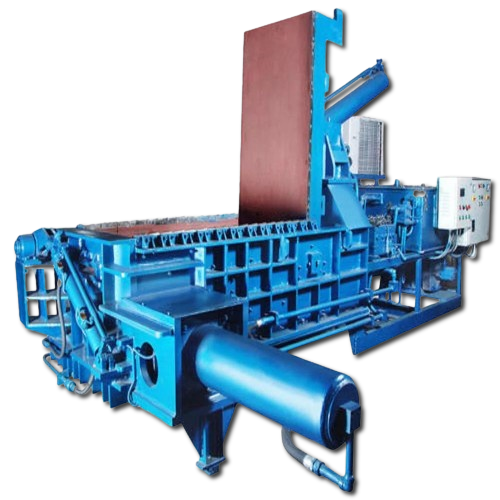

Erika Fluid Power is the best Hydraulic Pump Manufacturers in New Delhi. The Hydraulic Pumps that we make are super reliable in long terms of use and we have tested them in every way possible to ensure that they can withstand heavy usage. We design our power packs and hence it ensures efficient conversion of energy so that your equipment does its best. High efficiency saves energy and reduces operating costs. Our power packs are designed to be easily maintained, with all important components readily accessible and simple servicing procedures to reduce downtime and maintenance costs, keeping your operations running seamlessly.

Hydraulic Pump Exporters from Delhi

We are the punctual Hydraulic Pump Exporters from Delhi. Our power packs make use of advanced sealing technology to prevent any leaking or contamination of the internal components. This enhances durability and assures dependable performance. We design our power packs to run quietly, reducing noise levels in your working environment. This makes them more comfortable for operators to use and helps to ensure a quieter working environment. Our hydraulic power packs will provide reliable, low-cost power to your equipment so that it works better, and faster, increasing productivity and helping you get the job done fast.

Hydraulic Pump Suppliers in India

Consider us for all the needs of your Hydraulic Pump Wholesale Suppliers in India. We have made our power pack machines for reduced maintenance as well and over time you will save money as well hence it is ensured in our power packs by robustness and tight sealing. With less downtime and lower maintenance costs, continuous operations are guaranteed. Our power packs can stand tall for all kinds of rough conditions. From this kind of durability, be sure that your invested money will pay off in years of reliable performance. Quietly operating under their hoods, they provide a comfortable and quieter workspace for everyone working within that atmosphere.

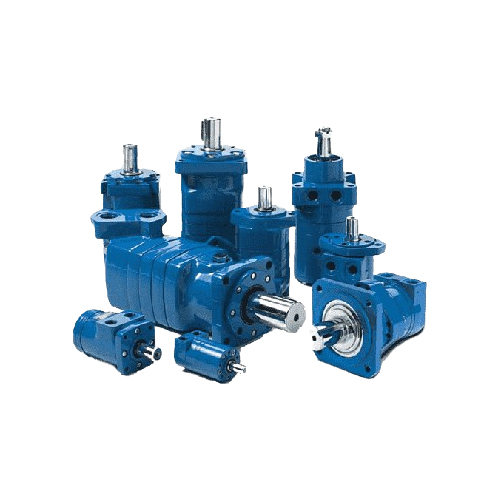

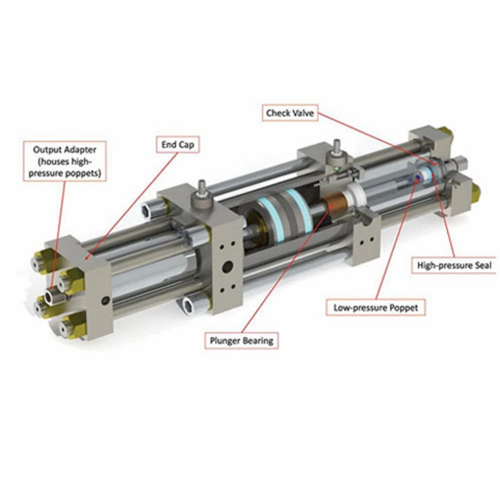

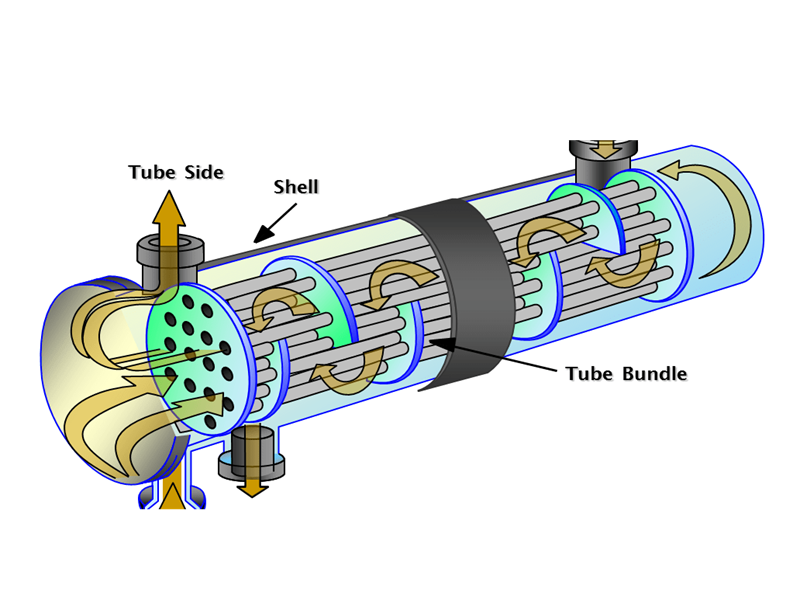

A hydraulic pump is a mechanical device used to convert mechanical energy into hydraulic energy by generating a flow of hydraulic fluid under pressure. This pressurized fluid is then used to power various hydraulic actuators and components in a hydraulic system. Hydraulic pumps are essential in various applications, from industrial machinery to automotive systems and aerospace technology.

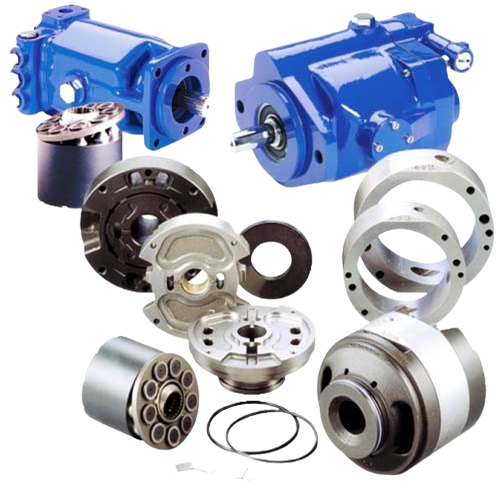

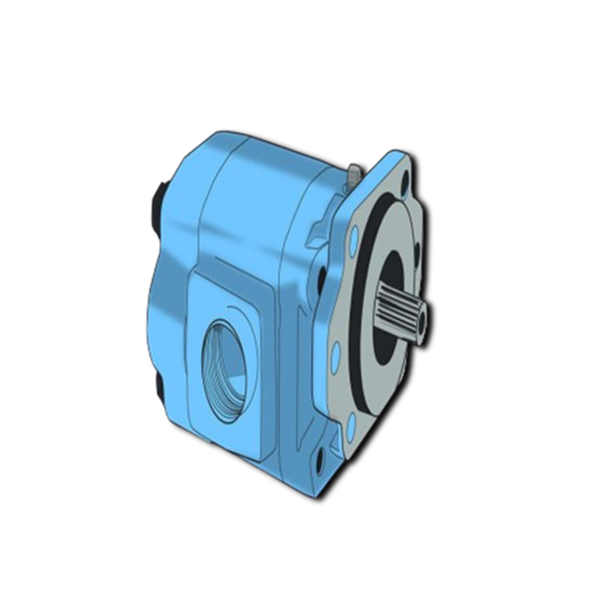

Gear Pumps: Consists of two interlocking gears—one drive gear and one idler gear—contained within a casing.

- Internal Gear Pumps: Feature a smaller gear (the inner gear) rotating inside a larger gear (the outer gear), both enclosed in a casing. Fluid is trapped between the gears and displaced through the pump.

- Vane Pumps: Feature a rotor with vanes that slide in and out of slots, creating chambers that expand and contract to move fluid. As the rotor turns, the vanes slide in and out, trapping fluid and pushing it through the pump.

- Rotary Vane Pumps: Similar to sliding vane pumps but with fixed vanes that rotate around a central axis. Fluid is moved by the rotation of the vanes and the changing volume within the pump.

- Piston Pumps Axial Piston Pumps: Feature pistons arranged parallel to the pump shaft, moving in an axial direction. As the shaft rotates, the pistons move back and forth within their cylinders, drawing fluid in and pushing it out.

- Radial Piston Pumps: Have pistons arranged radially around a central axis. Pistons move outward in a radial motion, displacing fluid within the pump.

- Gerotor Pumps: A subtype of gear pumps with a garroter mechanism, which includes a rotor and a stator with a specific gear profile. Fluid is drawn in and then forced out through the rotation of the rotor.

- Peristaltic Pumps: Use a rotating mechanism to compress a flexible tube or hose, pushing fluid through the tube.As the rollers or shoes compress the tube, fluid is forced through it in a controlled manner.

- Screw Pumps: Utilize one or more rotating screws to move fluid through the pump. As the screws rotate, they create a progressive cavity that moves fluid along the screw’s length.

- Diaphragm Pumps: Use a diaphragm to create a vacuum and move fluid through the pump. The diaphragm’s movement creates alternating pressure changes to move fluid in and out of the pump

- Displacement: 0.5 cc/rev to over 500 cc/rev

- Flow Rate: 0.5 L/min to over 2000 L/min.

- Pressure Rating: 100 psi to over 5000 psi (7 bar to 350 bar) depending on the pump type.

- Efficiency: 80% to 95%.

- Speed: 500 RPM to 3000 RPM.

- Temperature Range: 20°C to 100°C (-4°F to 212°F)